Mycie przemysłowe stalowych korpusów amortyzatorów samochodowych

Nasz klient globalny dostawca do przemysłu motoryzacyjnego, zgłosił się do nas z prośbą o pomoc w procesie mycia przemysłowego stalowych korpusów amortyzatorów samochodowych. Elementy te po procesie malowania wymagały usunięcia zanieczyszczeń organicznych takich jak olej czy pozostałości emulsji oraz nieorganicznych (metalowe wióry, włókna tekstylne). Czyste detale miały być przeznaczone do dalszego etapu montażu.

Czego potrzebował klient?

- Mycie ponad 40 różnych typów detali o złożonej geometrii i czasem skrajnie różnych kształtach i gabarytach

- Dostosowanie transportu detali poprzez proces mycia w sposób umożliwiający w przyszłości pracę z nowymi projektami i nowymi typami amortyzatorów – elastyczność rozwiązania w dużym zakresie zmian typów części

- Spełnienie rygorystycznych norm czystości na poziomie maksymalnej cząstki poniżej 500um

- Możliwość łatwego i szybkiego przezbrojenia urządzenia

- Poprawienia ergonomii pracy – załadunku i rozładunku – przy jednoczesnym zwiększeniu wydajności maszyny

Rozwiązanie wdrożone u klienta

Eksperci NOYEN zaproponowali proces mycia w urządzeniu typu tunelowego NOYEN EXPERT T. Standardowe urządzenie myjące produkowane przez firmę przez kilkanaście lat zostało zaprojektowane specjalnie pod wymagania klienta. W ramach projektu opracowana została pełna koncepcja linii, w której proces mycia rozpoczyna się manualnym załadunkiem amortyzatorów przez operatora na paletki transportowe. W urządzeniu zastosowana została koncepcja ułożenia detali na paletce, w pochyleniu o określony kąt, co pozwala na ergonomiczną pracę operatora prowadzącego załadunek i rozładunek, a także automatyczne przezbrojenie paletek na dany typ referencji i szybką zmianę programu mycia dla różnych detali. W tej koncepcji (będącej jednocześnie koncepcją foolproof) dodatkowym ułatwieniem dla operatora i czynnikiem wpływającym na skrócony czas załadunku jest brak konieczności dokładnego pozycjonowania elementu na paletce.

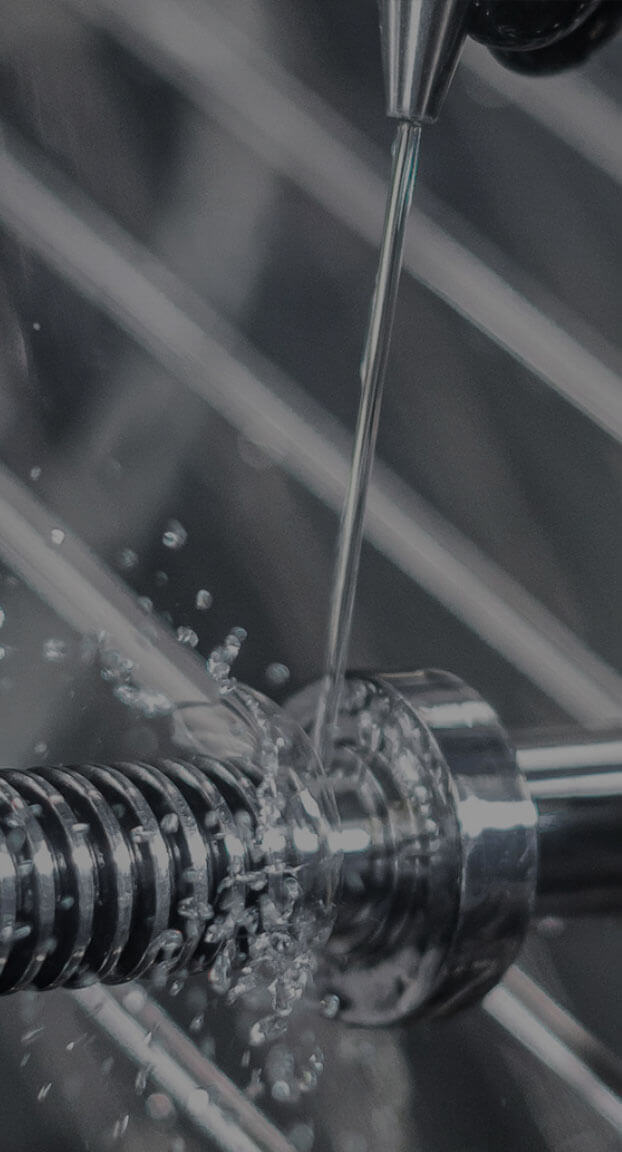

Następnie detale są poddawane procesowi mycia średnio- i wysokociśnieniowego na poziomie >42 bar za pomocą dedykowanych wsuwanych kolektorów natryskowych, które efektywnie usuwają zabrudzenia z trudno dostępnych miejsc, z wewnątrz amortyzatora. Kolejne sekcje to płukanie średniociśnieniowe > 5 bar i suszenie konwekcyjne (hot-air drying) kolektorami odmuchowymi oraz nożami powietrznymi. Ostatni element procesu to stabilizacja temperatury detalu do poziomu wymaganego przez klienta <43⁰C, aby wyeliminować konieczność użycia rękawic ochronnych przez operatora

Wszystkie procesy odbywają się jednocześnie, a detale są transportowane po 4 szt. co znacznie wpływa na wydajność procesu.

Co zyskał Klient dzięki współpracy z NOYEN?

- Zastosowanie automatycznie przezbrajających się paletek – > dla danego kodu kreskowego przypisana jest odpowiednia paletka transportowa dla typu detali z dedykowanym programem mycia

- Dedykowany program mycia, który optymalizuje wydajność, ponieważ jedne referencje są myte, płukane i suszone w standardowym czasie cyklu a inne w skróconym. Dzięki identyfikacji i trackingowi części i paletek myjnia automatycznie włącza dany program w danej sekcji

- Uzyskanie wysokiej wydajności = czasu mycia na poziomie 5s / 1 detal, 20s / paletkę (4 detale na paletce) w cyklu

- Uzyskanie wymaganych przez klienta norm czystości technicznej

- Obsługa czasem? skrajnie różnych referencji detali w jednym urządzeniu

- Powtarzalność załadunku i stabilność procesu

- Aplikacja będąca nie tylko myjnią przemysłową, ale także linią transportową, z automatycznymi wysokowydajnymi systemami, uwzględniającą ergonomię stanowisk operatorskich